Military Webbing

◆ SOLUTION PROVIDER

One-stop factory for high performance military textile products.

Including camouflage webbing, IRR webbing, US Mil Spec Webbing.

◇ MILITARY-GRADE MATERIAL

Nylon ( 6 or 6.6), semi-dull nylon, Polyester, Kevlar® (Nomex®).

◆ EXPERIENCE SUPPLIER

Over 15 years experience in defense, government and tender projects.

Width range: 5~150mm, thickness range 350~3000nm.

◇ QUALITY TESTED

Passed military requirement for MIL SPEC, UK/BS, TL, ASTM, AATCC, PIA etc.

◆ CUSTOMIZED FUNCTIONS

IRR(350-3000nm), camo printed, high strength, good color fastness etc.

◇ WIDE APPLICATION

* Soldier System * Tactical Vest

* Rucksacks and Luggages * Military Belt

* Parachute and Aerospace * Gun Sling Accessories

To find out our complete assortment of military webbing CONTACT US.

* LEARN MORE ON THE FOLLOWING PAGES.

Most of military webbing is made of nylon, polyester or aramid (Kevlar) etc. All materials are strong, lightweight webbing suitable for most military applications. We also provide dull nylon and dull polyester materials for a better match with fabric.

◆ Nylon / PA:

We provide a wide range of nylon material including nylon 6, high tenacity nylon, nylon 6.6. Nylon is Hygroscopic- will absorb water and loses some tensile strength and results in more potential increased elongation.

◆ Polyester / PES:

Polyester has a higher rate of initial loading with a flatter load over time, ranging from 6% to 18%. Polyester has less tensile loss when subject to moisture.

◆ Aramid / Kevlar:

Very strong material, is more resistant to damage from heat, fire and chemicals, making it critical in many military applications.

◆ Strength: Excellent

◇ Stretch: Moderate

◆ Anti-Abrasion: Excellent

◇ Anti-UV: Excellent

◆ Anti-Mildew: Excellent

◇ Anti-Flame: Excellent

◆ Strength: Excellent

◇ Stretch: Very Low

◆ Anti-Abrasion: Very Good

◇ Anti-UV: Good

◆ Anti-Mildew: Excellent

◇ Anti-Flame: Excellent

◆ Strength: Excellent

◇ Stretch: Very Low

◆ Anti-Abrasion: Very Good

◇ Anti-UV: Poor

◆ Anti-Mildew: Excellent

◇ Anti-Flame: Very Good

We offer military webbing in various weaves, specs, colors and functions.

Printed military webbing and binding tape are also available.

Provide trial order service, an assortment of stocked webbing.

Experienced in custom mass production as customer's requirement.

◇ Width: 5-150 mm, common size ( 20, 25, 38, 50mm / 3/4", 1", 1.5", 2" )

◆ Thickness: 0.3-5 mm

◇ IRR: 350-3000 nm with test report

◆ MIL SPEC Types: 17337, 55301, 5038, 5625, 4088/27265, 87130 etc

◆ Asia's largest manufacturer of military webbings.

◇ Produced military webbing for defense project: 20+ years

◆ Experience for 50+ countries defense & government projects:

▷ UK ▶ Czech

▶ Netherlands ▷ Italy

▷ France ▶ Sweden

▶ Finland ▷ Switzerland

▷ Singapore ▶ Canada

▶ Philippines

More webbings experience are not listed, please CONTACT US.

We manufactured wide lines of military webbnig for soldier system, including MIL SPEC webbing, MOLLE webbing, PALS webbing, in the most strict quality control.

Our SOLDIER VEST & BACKPACK WEBBING advantages:

◆ Wide Application: military packs, army rucksack, navy haversacks, air force bags etc

◇ Common types: Mil-W-17337, A-A-55301, Mil-PRF-5038, Camo Printed etc

Please CONTACT US if you would like to get our webbing test reports.

Printed Military Webbing are also offered.

We produced belt webbing in military quality nylon material, in high strength, durable and breathable. We also provide cutting, sewing and processing service for military belt.

Our BELT WEBBING advantages:

◆ Application: soldier belt, police and security belt, rifle straps, tactical gears etc

◇ Standard Width: 32, 38, 45, 48, 50 mm / 1.5", 1.75", 2" ( Support customization )

◆ Common Thickness: 1.5-2.8 mm ( Support customization )

◇ Common Weave: Ribbed, tank, plain, bead, PIA-4088 type 7 ( Support customization )

◆ Breaking Strength: 38*2.45 mm- 3421 kg/ 7542 lbs ( Ref. high strength nylon)

◇ Colour: Military color ( Black, OD Green, Coyote, Tan, Ranger Green, Navy, Gray, Camo, Custom )

◆ Colour Fastness: 4-5 grade ( Higher than standard 3-4 )

◇ Belt Series: COBRA belt, BDU, EDC, CQB etc ( Support customization )

Please CONTACT US if you would like to get our webbing test reports.

Printed Belt webbing are also offered.

We are experienced in produced wide ranges of parachute standard webbing with tested. Most of airborne webbing are made of nylon 6.6, and available in resin treatment as specification.

Our PARACHUTE WEBBING advantages:

◆ Wide Application: airborne force bag, airdrop cargo nets, paratrooper harness etc

◇ Common types: PIA-W-4088 Type 1, 4, 7, 8b, 13, 17 etc, Mil-PRF-5038 Type 3, Mil-W-5625 Tubular etc

Please CONTACT US if you would like to get our webbing test reports.

More types of parachute webbing are also offered.

We also provide tent webbing in military quality nylon or polyester material, providing UV protection under extreme weather condition. Other functions including water repellent, fire repellent, quick-drying are also offered.

Our TENT WEBBING advantages:

◆ Application: military shelter, outdoor tents, gazebos and tarpaulins etc

◇ Standard Width: 15, 20, 25, 38, 50 mm / 3/5", 3/4", 1", 1.5", 2" ( Support customization )

◆ Common Thickness: 0.40-2.00 mm ( Support customization )

◇ Common Weave: plain, bead, binding tape, central holes webbing ( Support customization )

◆ Breaking Strength: 25*0.40 mm- 283 kg/ 624 lbs ( Ref. high strength nylon)

◇ Colour: Military color ( Black, nato Green, Coyote, Tan, Ranger Green, Navy, Gray, Camo, Custom )

◆ Colour Fastness: 4-5 grade ( Higher than standard 3-4 )

Please CONTACT US if you would like to get our webbing test reports.

Printed tent webbing are also offered.

◆ Full supply chain: weaving, dyeing, printing and processing

◆ ISO 9001 & 14001, OEKO-Tex 100 certificated

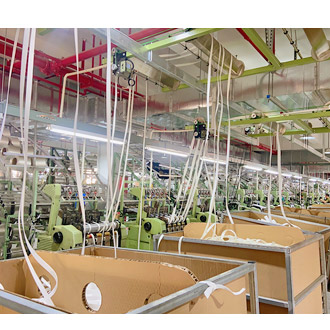

ADVANCED EQUIPMENT

◆ Daily webbing output 100,000 meters

◆ Leading intelligent printing machine

◇ 9 lines of silkscreen printing

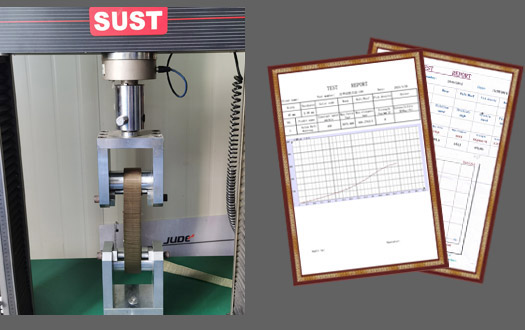

◆ BREAKING STRENGTH

◆ BREAKING STRENGTH We have our own breaking strength testing machine, with control of each batch requirement if have. Including tensile strength, elongation, break time etc.

* Passed: ASTM D6776, ISO 13937, GB/T 3923 etc

◇ INFRARED REFLECTANCE

◇ INFRARED REFLECTANCE* Experienced in: 600-860nm, 800-1250nm, 650-1250 nm etc

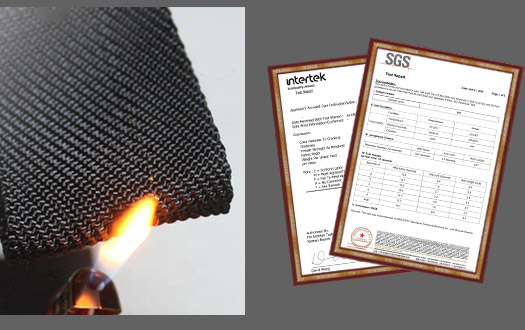

◆ FIRE RETARDANT

◆ FIRE RETARDANT With the capacity to do post-treatment of various kinds of fiber webbing into flame retardant, no melting drop. After flame 15.0 seconds, Drip burn 5.0 seconds, Burn Length 8.0".

* Passed: FAA FAR 25:853, ISO 3795, ASTM 6413, GB/T 5455 etc

◇ JUDE WEBBING TESTING CENTER

◇ JUDE WEBBING TESTING CENTER* Tested in Mil Spec, UK / BS, TL, ASTM, AATCC, PIA, ISO 104 etc

◆ BULK EXPERIENCE

◆ BULK EXPERIENCE Annual military webbing export output more than 1,000,000,000 of meters, with batch to batch repeatability.

◇ STRICT Q&C

◇ STRICT Q&C Controlled delivery time. A leading on-demand manufacturer that delivers high volume orders at request time.

◆ FAST DELIVERY

◆ FAST DELIVERY With rich transportation experience and the logistics supply chain, and can even assist to deliver goods directly to your doorstep.