Kevlar & Dyneema® (UHMWPE) Webbing | Silicone Grip Printed Webbing for Safety Gear & Outdoor Equipment

Email:

judecam@judegroup.com

Wechat:

86-0592-6361058

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Details

- 产品优势

-

Introduction

Our UHMWPE (Dyneema®) and Kevlar webbing with silicone printing offers unmatched strength, durability, and customization. Designed for tactical equipment, safety gear, and high-performance outdoor applications, this webbing combines two of the strongest fibers in the world with a silicone-printed grip surface and custom logo branding.

Key Features

✔ Dual-fiber construction: White UHMWPE (Dyneema®) and natural Kevlar for maximum performance

✔ Silicone printed surface: Provides anti-slip grip and durable logo customization

✔ Extreme tensile strength with lightweight performance

✔ Abrasion, cut, and heat resistance

✔ Low stretch, high stability under heavy load

✔ OEM logo & pattern printing available

Technical Specifications

Property UHMWPE Webbing Kevlar Webbing Base Material UHMWPE (Dyneema®) Kevlar® (para-aramid) Color White Natural Yellow Width 20–50 mm 20–50 mm Printing Silicone Grip / Custom Logo Silicone Grip / Custom Logo Tensile Strength ≥ 30 kN ≥ 25 kN Abrasion Resistance Excellent Excellent Cut Resistance High Very High Heat Resistance 80–100°C 300–400°C Customization Logos, Colors, IRR/FR Coatings Logos, Colors, IRR/FR Coatings

Applications

-

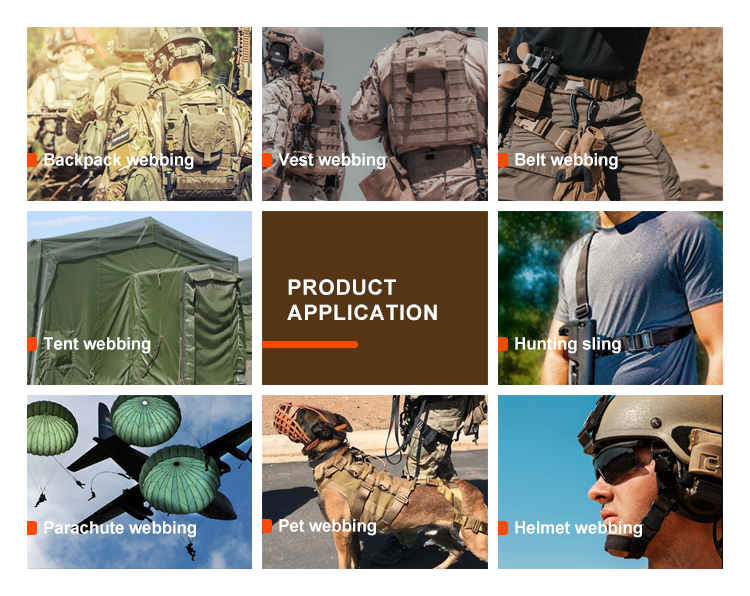

Tactical belts & vests with anti-slip function

-

Outdoor and climbing gear requiring extra grip

-

Industrial safety harnesses

-

Rescue and protective equipment

-

Custom-branded gear straps

Why Choose Us

-

In-house printing & customization (logos, silicone grip, color options)

-

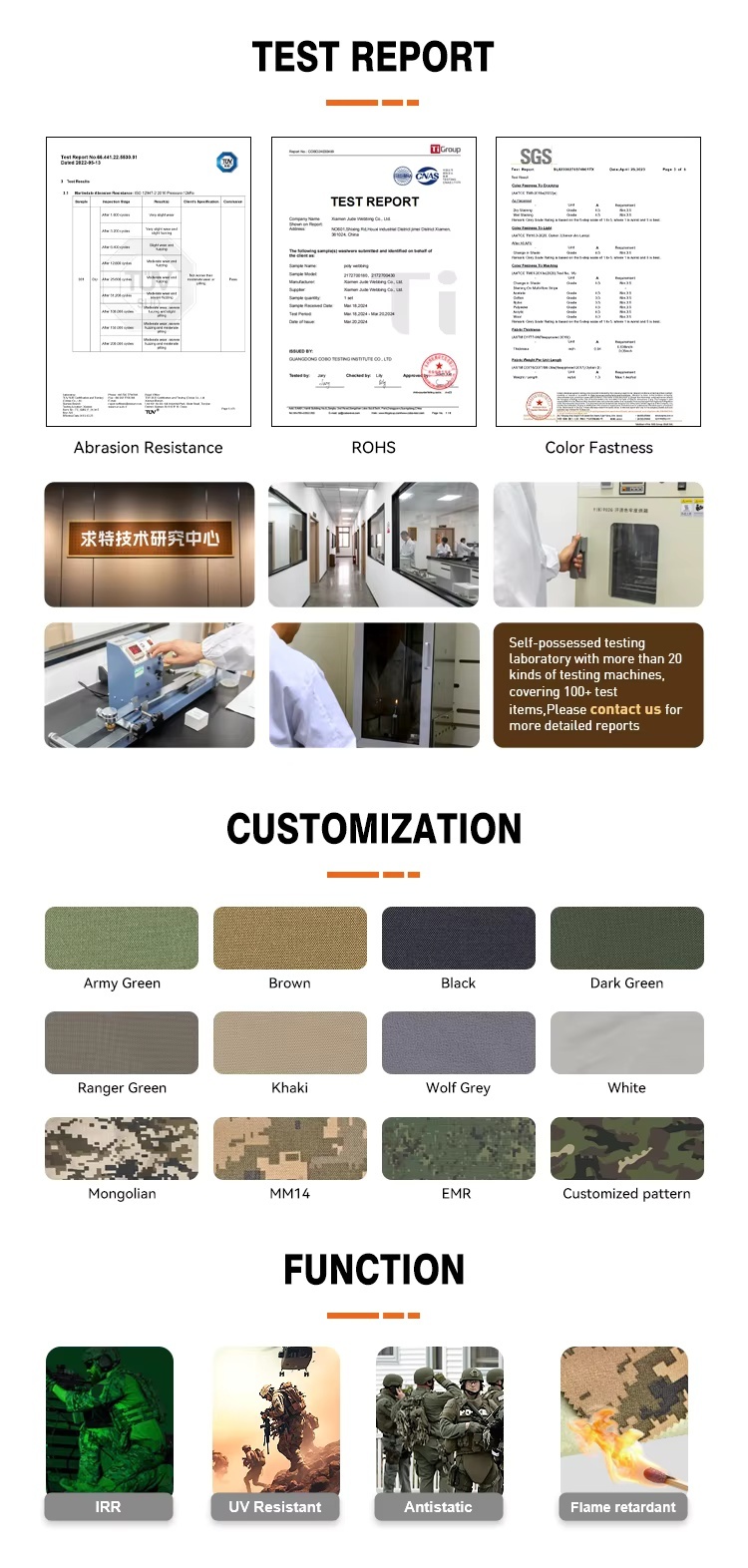

Factory + testing lab ensures reliable performance

-

Experience in military-grade webbings with Kevlar & UHMWPE

-

Support for low MOQ prototypes and large-scale production

FAQ

Q1. What makes your safety webbing different from standard polyester webbing?

A1. Our safety webbing is engineered with special fibers like aramid or UHMWPE to resist high temperature, abrasion, and cutting — far exceeding the strength and durability of ordinary polyester straps.Q2. Do you have flame-retardant or fireproof webbing options?

A2. Yes. Our fireproof webbing meets test standards. It remains stable and non-melting even at ultra-high temperatures, ideal for firefighting, rescue, and industrial safety gear.Q3. How do you test the cut-resistant performance of your webbing?

A3. We evaluate cut resistant webbing using controlled abrasion and edge-load tests to simulate sharp-object contact. UHMWPE and aramid fibers both provide exceptional cut and tear resistance.Q4. Can your webbing maintain strength under chemical or outdoor exposure?

A4. Yes. Our UHMWPE webbing and aramid webbing retain tensile performance after prolonged UV, chemical, and moisture exposure, making them suitable for harnesses, fall protection, and lifting systems.Q5. Do you produce safety webbing in different widths or constructions?

A5. Yes. We customize from 10 mm to 100 mm width, available in tubular, flat, or double-layer structures according to specific safety webbing requirements.Q6. Do you produce webbing for rescue or fall-protection systems?

A6. Yes. We supply aramid and UHMWPE safety webbing for industrial lifting, harness, and rescue equipment, designed to maintain tensile strength under extreme load or abrasion.Q7. Can you customize the construction or coating?

A7. Yes. We offer tubular or double-layer structures, resin coatings, and reflective, waterproof flame-retardant finishes — all developed in our own R&D team.🔗 Learn more: [View full FAQ library →]

-

-

Advantages

- Material: Kevlar & Dyneema® (UHMWPE)

- Features: Ultra-high strength, cut resistant, anti-slip etc

- Application: Rescue and protective equipment

Customized

- Width: 50 mm

- Color: off white, natural color

- Packaging: 50 meters/roll

Kevlar & Dyneema® (UHMWPE) Webbing | Silicone Grip Printed Webbing for Safety Gear & Outdoor Equipment

Advantages

- Material: Kevlar & Dyneema® (UHMWPE)

- Features: Ultra-high strength, cut resistant, anti-slip etc

- Application: Rescue and protective equipment

Customized

- Width: 50 mm

- Color: off white, natural color

- Packaging: 50 meters/roll

Still deciding? Get samples first, Contact US !

Email:

judecam@judegroup.com

Products Category

Share to

Inquire Now

We will contact you within one working day. Please pay attention to your email.

Related Products