Welcome to JUDECAM - High Performance Webbing Manufacturer

Tel: 0086-0592-6361058 E-mail: judecam@judegroup.com

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

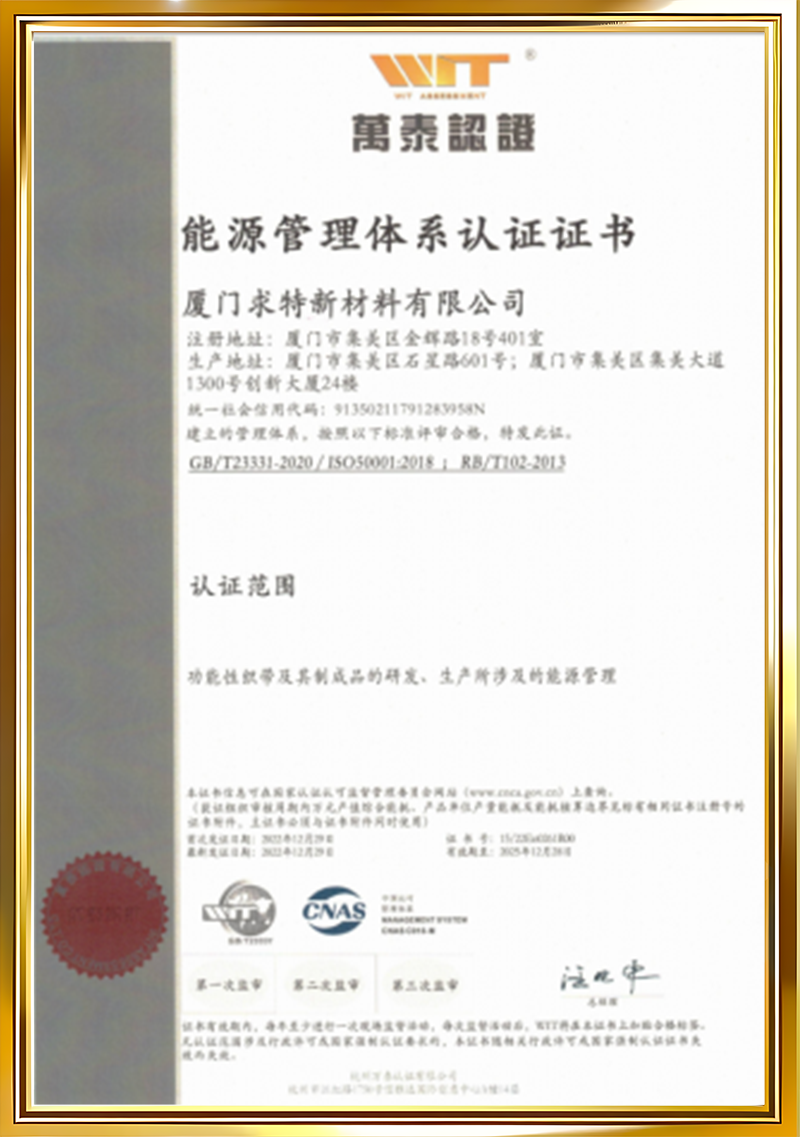

QUALITY

Choose JUDE to get a quality experience

QUALITY ASSURANCE

Excellent Quality, Beyond Expectations

Production Capacity

As an ISO 9001 certified functional webbing manufacturer, we ensure consistent output and reliable lead times for both small runs and bulk orders. Our production capacity supports stable supply and reduces risks for global buyers.

Jude webbing has a self-built production base of 25,800 square meters, with full industrial chain production capacity of weaving, printing, dyeing and finishing, and assembly.

Highlights:

- Stable delivery: Controlled planning guarantees on-time shipment.

- Consistent quality: Uniform standards across all technical webbing batches.

- Long-term partnership: Flexible lines support prototyping and mass production.

Professional Testing Center

|

Experimental testing capabilities (partial display) |

|

|

Physical properties testing |

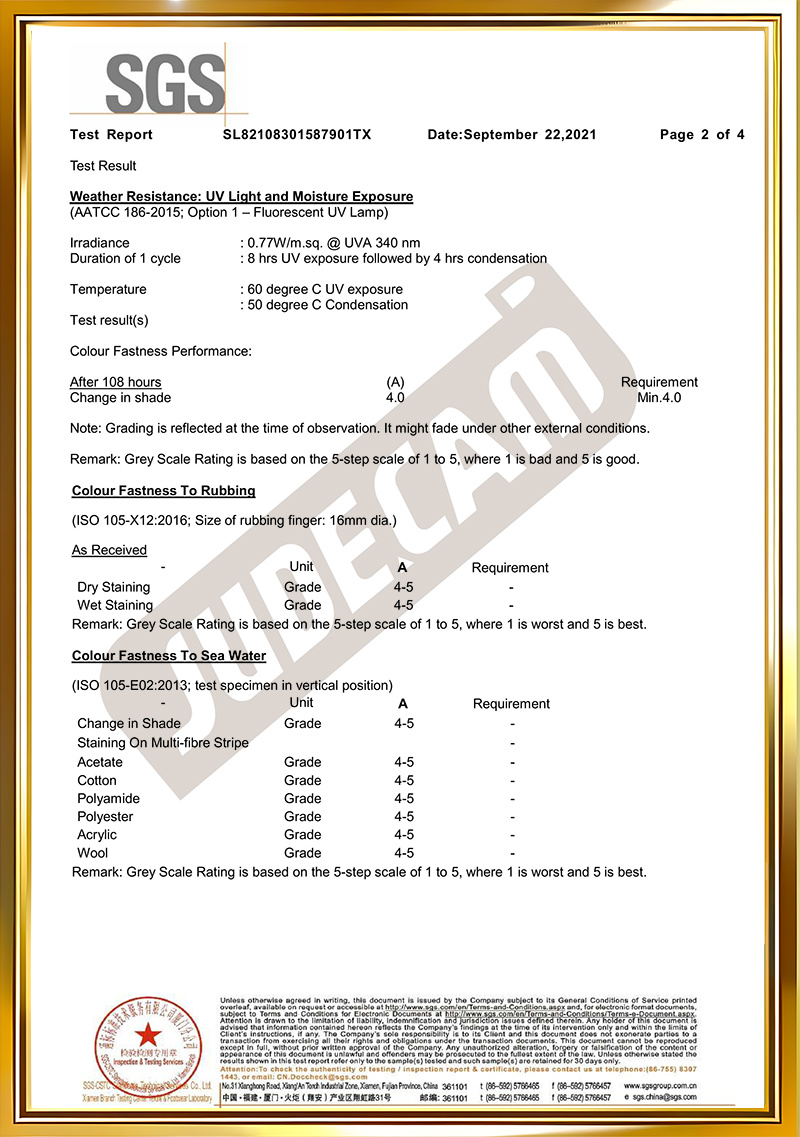

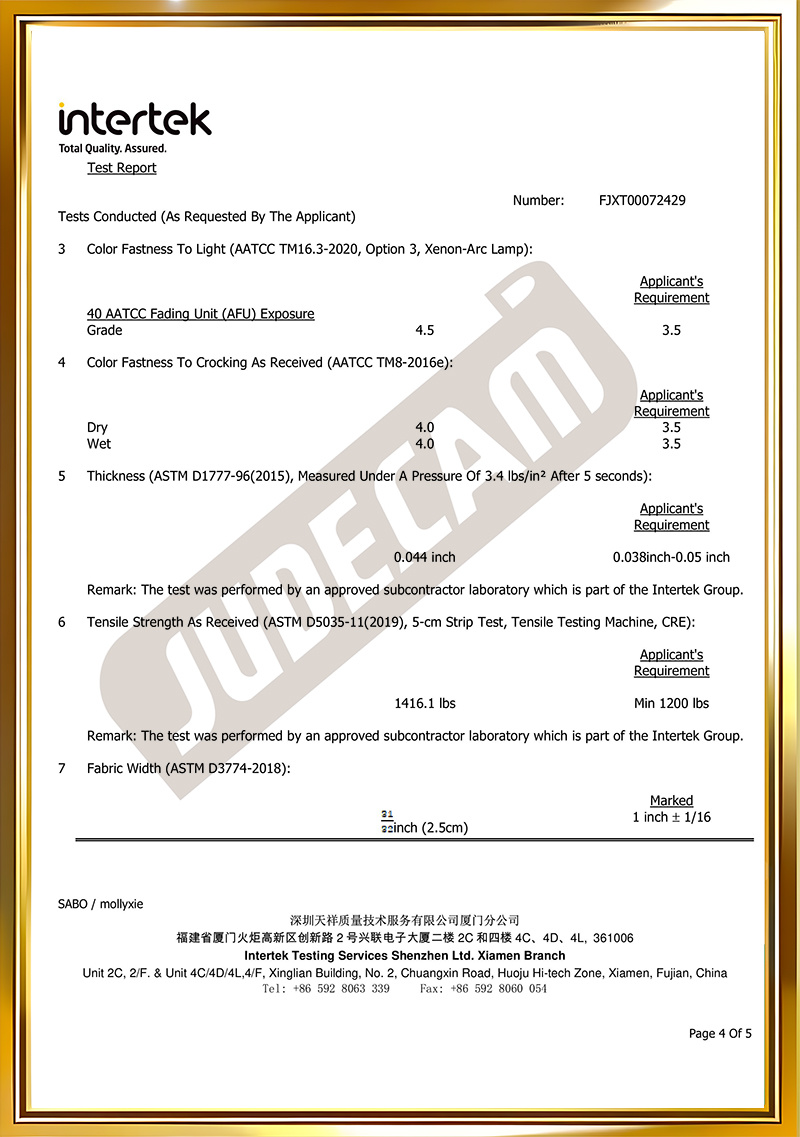

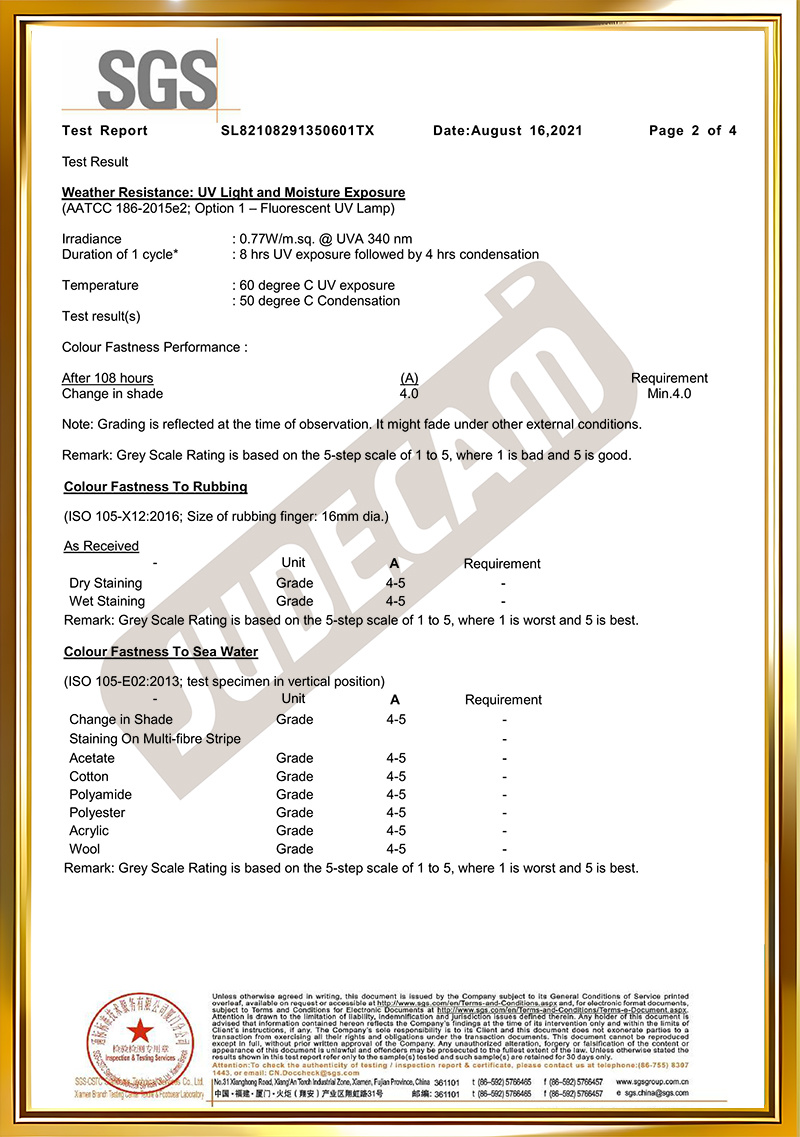

Color fastness to rubbing |

|

Color fastness to perspiration |

|

|

Color fastness to washing |

|

|

Digital yarn twist test |

|

|

Fully automatic shrinkage test |

|

|

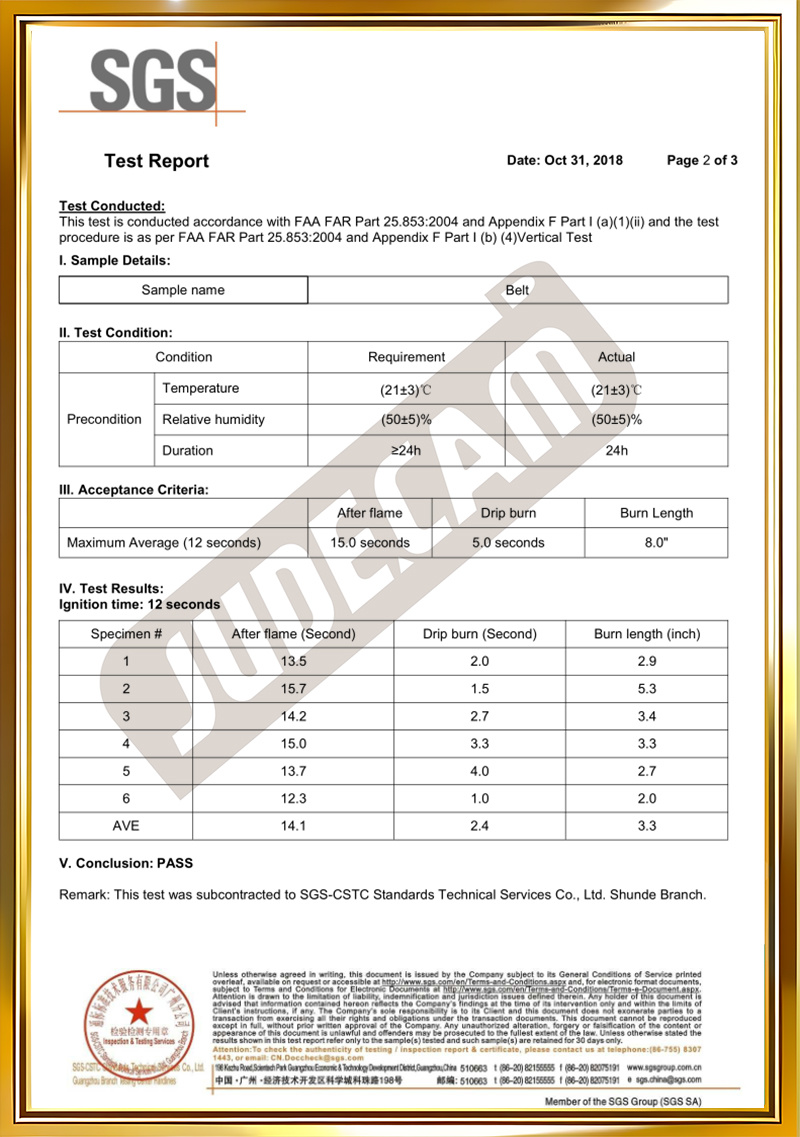

Flame retardant performance test |

|

|

Seat belt wear resistance test |

|

|

Chemical properties testing |

Formaldehyde content test |

|

Sunlight climate testing |

UV color fastness test |

|

Ultra-low temperature testing |

Ultra-low temperature storage performance |

|

Constant temperature and humidity testing |

Breaking strength |

|

Width, thickness, color |

|

|

Yarn length measurement |

|

|

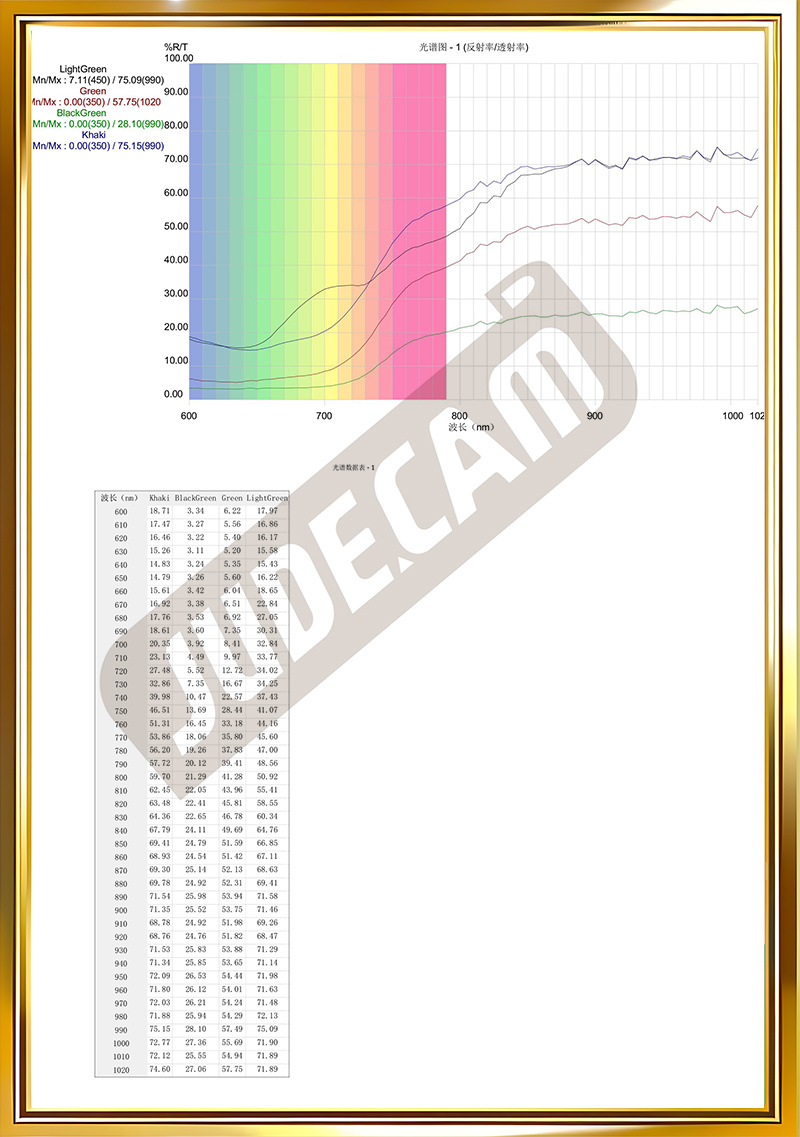

Anti-infrared spectrum data |

|

Our in-house professional narrow fabric textile testing center validates tensile strength, abrasion resistance, and colorfastness against ISO, ASTM, AATCC and MIL SPEC webbing requirements. Faster, reliable testing ensures compliance without delays.

Highlights:

- Faster approvals: Internal testing accelerates validation.

- Compliance confidence: Results benchmarked to global standards.

- Risk reduction: Early detection prevents large-scale failures.

Exclusive Team

150+ webbing production workers, 30+ webbing experts, professors, graduate tutors and senior engineers lead a 32+ member professional R&D technical team.

We set up exclusive production/sales/R&D working groups for each customer to help customers avoid procurement and application risks, save costs and improve efficiency.

Our independent QA team focuses solely on quality assurance for technical webbings and straps. They ensure unbiased inspections and continuous alignment with customer requirements.

Highlights:

- Strict standards: Every shipment validated by QC specialists.

- Peace of mind: Proactive follow-up and improvement processes.

- Brand trust: Reliable OEM webbing supplier committed to long-term quality.

Xiamen Jude Webbing Co., Ltd.

Tel: 86-0592-6361058

E-mail: judecam@judegroup.com

Factory Address: No. 601 ShiXing Road, Jimei District, Xiamen, 361024, China

Request Quote

We will contact you within one working day. Please pay attention to your email.

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSASE-SFZ

https://dc.thefastmake.com/index.html?configure=--enable-dom-interceptor