Welcome to JUDECAM - High Performance Webbing Manufacturer

Tel: 0086-0592-6361058 E-mail: judecam@judegroup.com

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

BLOGS CENTER

Choose JUDE to get a quality experience

Flame Retardant MIL-W-4088 Type 7 Webbing for Military Parachute Applications | Certified 4088 Webbing Supplier

Jul 29,2025

When it comes to military parachute and cargo restraint systems, performance is not an option—it's a requirement. For defense contractors, government procurement agents, and aerospace system integrators, the choice of webbing must meet the most demanding military and aviation standards.

One of the most trusted options is MIL-W-4088 Type VII webbing, particularly when manufactured from flame retardant nylon. This high-strength, PIA spec tested & certified webbing is engineered for use in airborne troop deployment, cargo drops, and other aerospace safety systems that require durability, flame resistance, and traceable compliance.

📌 Product Overview: MIL-W-4088 Type VII Flame Retardant Webbing

-

Specification: MIL-W-4088 Type VII (aka Type 7)

-

Material: High tenacity nylon 6.6, flame retardant

-

Breaking Strength (MBS): ≥ 6,000 lbs (26.7 kN)

-

Width: 1-23/32" ± 1/16" (approx. 43.7 mm)

-

Weave Structure: Shuttle loom woven for edge stability

-

Color: Black

-

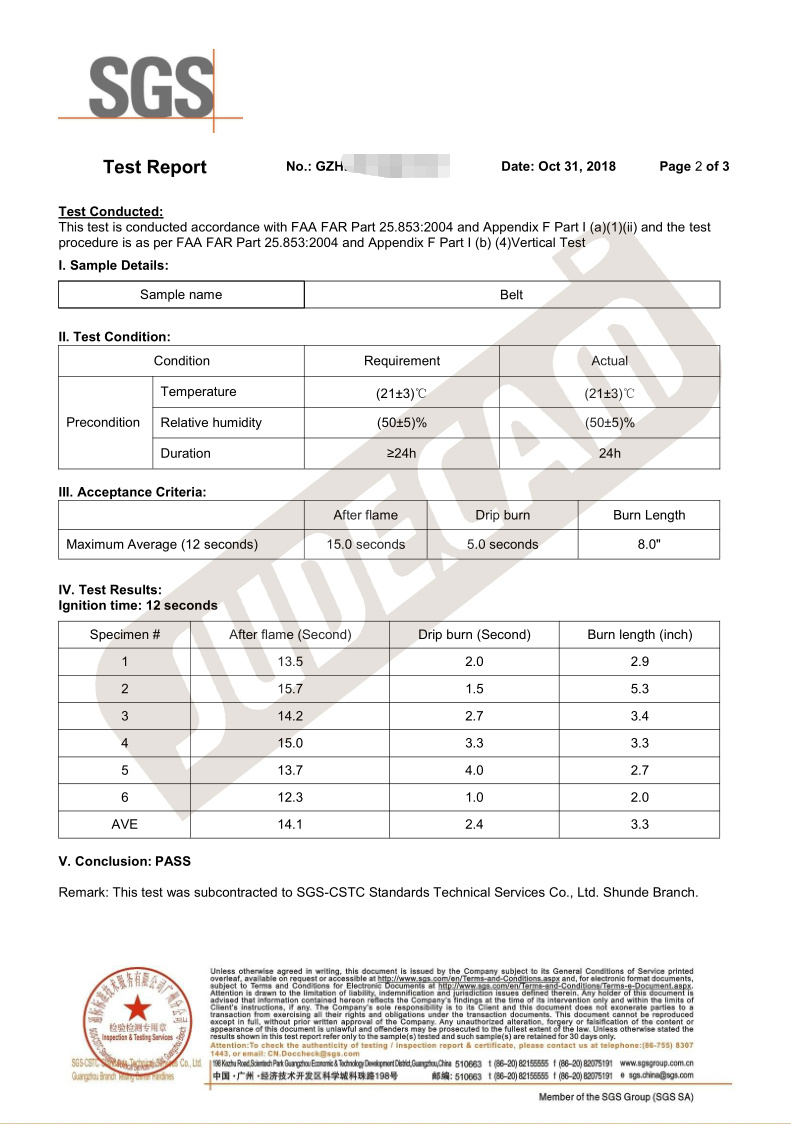

Conformance: FAR 25.853 (Flammability standard for aircraft interiors)

-

Testing: Tensile strength, shrinkage, elongation, flammability—all tested in-house

👉 Learn more: View full product specifications and datasheet here

💡 Why Is Flame Retardancy Important in Type VII Webbing?

In airborne applications, flammability is a mission-critical safety risk. Type VII webbing is used in parachute risers, harness assemblies, and cargo restraint systems—components that may be exposed to extreme environmental stress and elevated temperatures.

Flame retardant treatment ensures:

-

Slower ignition time during aircraft fires

-

Reduced heat release rate

-

Greater survivability in emergency descent or cabin incidents

For military equipment suppliers, selecting a webbing that passes FAR 25.853 is often a government-mandated requirement for airworthiness certification.

🔍 Who Needs MIL-W-4088 Type VII Flame Retardant Webbing?

This product is widely requested by:

-

Defense contractors and aerospace OEMs

-

Military parachute system manufacturers

-

Government procurement agencies

-

Aviation safety gear developers

-

Industrial rigging and restraint solution providers

Its flame retardant performance, along with military spec compliance, makes it ideal for contract bidding and long-term supply agreements.

🏭 Why Choose Us as Your Webbing Manufacturer?

As a direct webbing manufacturer with shuttle loom weaving and in-house testing facilities, we provide:

-

📦 Custom lot production per contract spec

-

📊 Full test reports for tensile strength, elongation & flame resistance

-

🌐 Global delivery with export documentation

-

🔎 Consistent quality with traceable inspection records

-

💬 Fast response to RFQs from procurement teams

Whether you're building a new parachute line or upgrading restraint systems, we support your team with compliant, certified and scalable webbing solutions.

Related Posts

Contact Us

E-mail:

Phone/WeChat:

Factory Address:

No. 601 ShiXing Road, Jimei District, Xiamen, 361024, China

Xiamen Jude Webbing Co., Ltd.

Tel: 86-0592-6361058

E-mail: judecam@judegroup.com

Factory Address: No. 601 ShiXing Road, Jimei District, Xiamen, 361024, China

Request Quote

We will contact you within one working day. Please pay attention to your email.

SAF Coolest v1.3.1.2 设置面板 GAGSD-AGYF-JSASE-SFZ

https://dc.thefastmake.com/index.html?configure=--enable-dom-interceptor